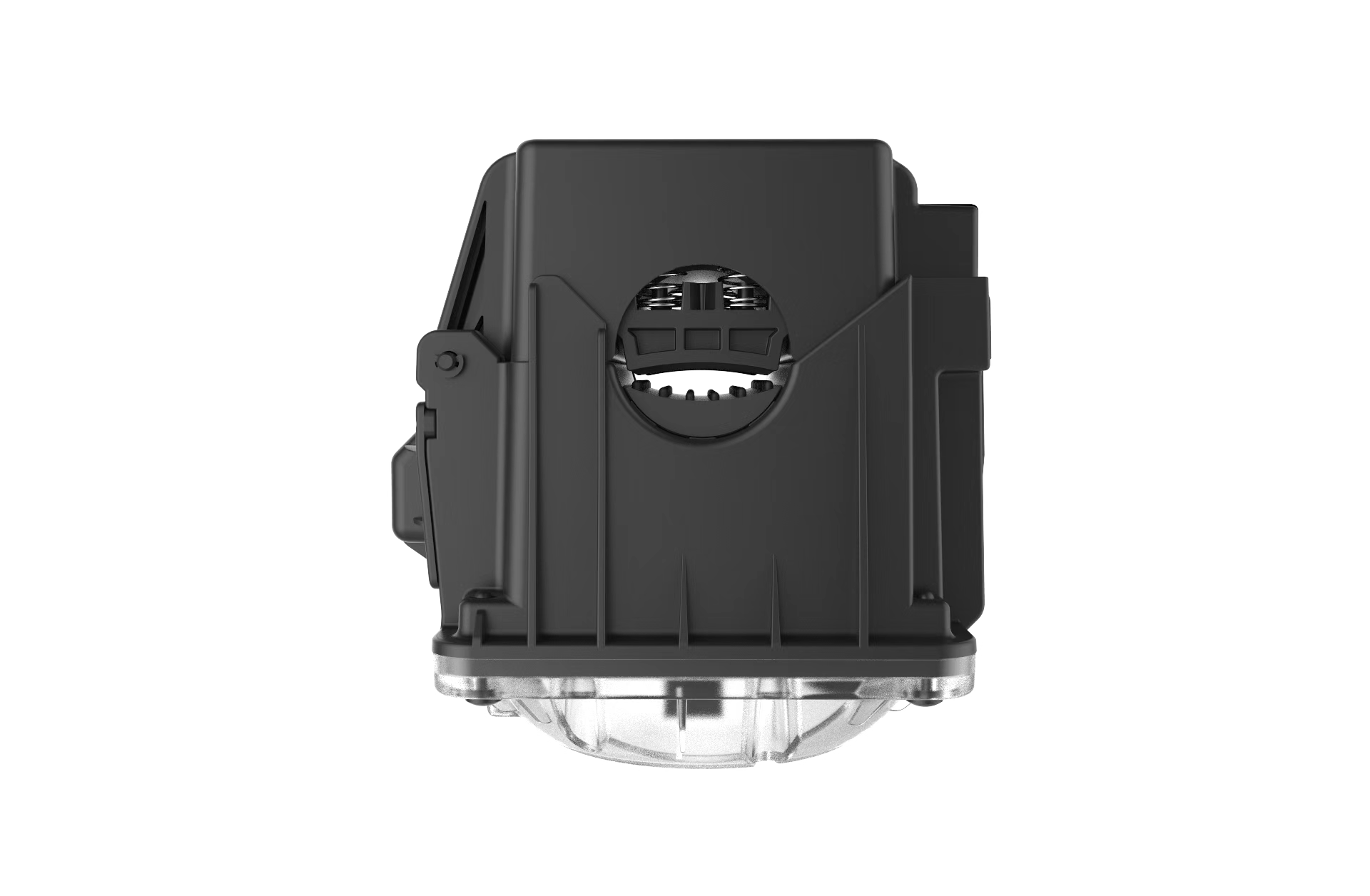

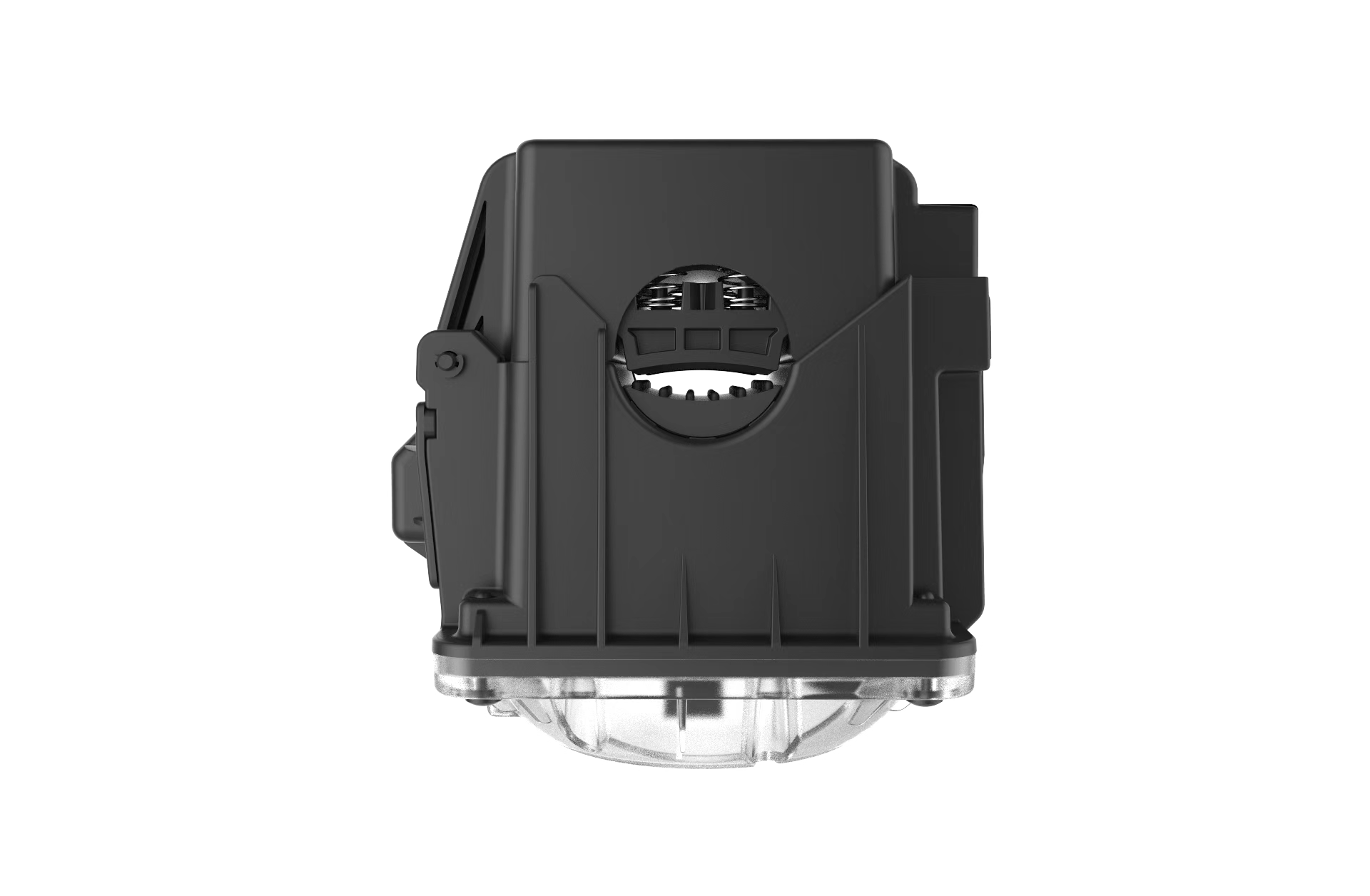

Product Overview:

The MV Fault Locator is specifically designed for 6-69kV overhead lines. It captures and analyzes the waveform at the moment of a fault to identify the fault cause. This enables rapid fault location and resolution, reducing fault detection and repair times, and ultimately improving power supply reliability. With a high-brightness flashing indicator, it ensures clear and immediate fault identification on-site.

Product Features:

1. Low Stress Wire Compression Design

- Prevents damage to cable insulation.

- Passes the double 85 test for 800 hours, ensuring 8 years of outdoor durability.

2. Hot Plate Welding Technology

- Hot plate welding with an integrated housing design.

- IP68 protection ensures complete prevention of water ingress outdoors.

3. Innovative Electric Field Measurement Technology

- Resistant to environmental interference.

- Multiple intelligent start-up options to suit various conditions.

4. Dual Magnetic Core Floating Design

- Operates fully at just 2A line current (High-energy version operates at 1A).

5. Position Locking Mechanism

- 0A to 100A, with an accuracy of ±0.5A.

- 100A to 600A, with an accuracy of ±0.5%.

- Accurately detects high-resistance grounding faults.

6. Electric Installation Tools

- Live installation

- remote control installation

- remote disassembly

Key Advantages:

- Precise Fault Location:Quickly and accurately identify fault points.

- Comprehensive Fault Detection:Detects common MV faults such as insulator damage, lightning arrester failure, line disconnections, transformer issues, and tree obstructions.

- Cost-Effective Repairs:Speeds up repair times and reduces overall labor costs.

- EnhancedService Reliability: Minimizes outage durations for better service.

- Hassle-Free Installation: No need for power shutdowns or elevated work platforms (EWP).

- Remote Monitoring:Supports 4G data transmission for real-time SCADA

- Clear On-Site Indication:Features a high-visibility indicator for easy fault identification.

Application Scenarios:

1. Substation Line Selection Monitoring:

- Installation Method: A fault locator is installed at each line outlet from the substation.

- Benefit: Eliminates manual line reconnection and reduces outage occurrences.

2. Line Segmentation Monitoring:

- Installation Method: Each line is divided into segments, and a fault locator is installed at each segment.

- Benefit: Accurately pinpoints fault segments, enabling quick troubleshooting and reducing downtime.